Plate Mounting Solution

Showing all 4 results

-

Plate Mounting Solution

Cloth Mounting tape

Cloth Mounting Tape is a double-sided tape of 380 μm (15 mil) thickness with a cloth backing and a rubber adhesive.

The product design makes this tape especially suitable for corrugated postprint plate mounting, where the tape is first applied to the printing plate, then the liner is removed and the plate is attached to the carrier film.

The cloth backing provides a high degree of flexibility, facilitating easy plate mount, while the well-proven adhesive ensures a reliable yet removable bond between printing plate and carrier film.

The unique liner structure prevents air trapping during plate mounting.SKU: n/a -

Plate Mounting Solution

Cushion Mounting Tape

Achieve high quality standard combination print with our Cushion Mounting Tape . It’s a double coated, foam tape with an air release feature adhesive for easy plate side removal and mounting of flexographic plates to print cylinders.

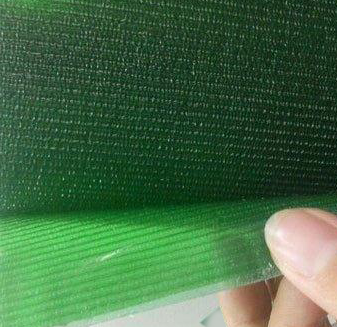

With easy mount adhesive is created for mounting flexographic print plates to cylinders or sleeves. It provides high quality standard combination print, and is suitable for combination of solids and tone reproduction where solids and process are equally important. Our Easy Mount liner creates micro-channels in both adhesive surfaces. The crosshatched pattern creates a continuous and permanent network of micro-channels in the adhesive, allowing air to escape from between the tape and cylinder/sleeve and between the tape and plate. The adhesive on the linered side (plate side) of the tape is designed for mounting photopolymer plates, has excellent holding power on-press and clean plate removal when demounting. The adhesive on the non-linered side (cylinder side) of the tape is designed for mounting to flexographic printing cylinders or sleeves, providing easy application while mounting and clean removability when demounting.

SKU: n/a -

Plate Mounting Solution

Edge Sealing tape

Plate-edge sealing is the perfect example of an ounce of prevention. It’s a quick, easy step in the flexographic process that acts as an insurance policy for your print runs. It ensures the edge of the plate stays put on the sleeve. Plate-edge sealing also provides a barrier to keep solvent from getting underneath the plate, which can cause the edge to lift. Then you’ve got the aggravation of a messy sleeve and problems like reduced print quality. Why risk poor quality when it’s so simple to prevent?

SKU: n/a -